“3D printing allows us to go beyond form — it invites us to rethink matter itself. It’s a dialogue between hand and machine, where every tension, every force, every density is precisely calculated. The result: a new kind of form — efficient, essential, almost anatomical”

TA.TAMU, Dassault Systèmes

Soon to be unveiled on June 24th, 2025, Ta.Tamu is a single-piece, fully 3D-printed functional, and foldable chair. Developed as an evolution of the Tamu chair, it reflects Patrick Jouin iD’s continued commitment to pushing the boundaries of design and exploring new creative possibilities with Dassault Systèmes.

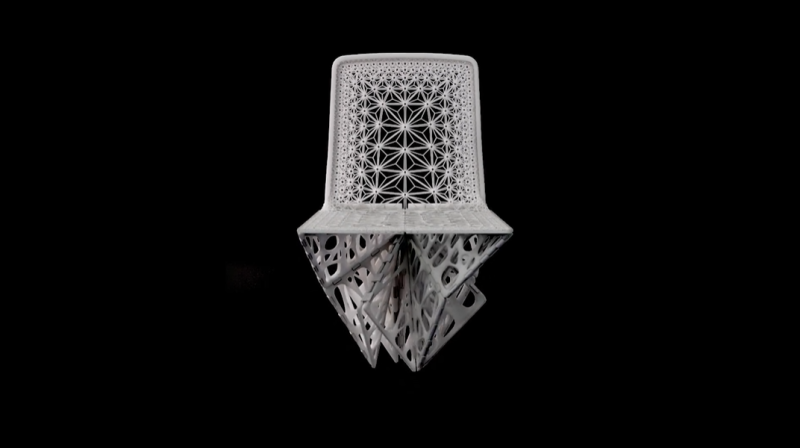

TAMU, Dassault Systèmes

Unveiled in 2019, Tamu is a life-sized 3D-printed prototype chair. It emerged from a collaboration between Patrick Jouin iD and Dassault Systèmes, combining generative design, topology optimization software, and the 3DEXPERIENCE platform.

Our objective was to significantly reduce material usage and create an ultra-lightweight object by working not with mass, but with the absence of mass. Tamu is the result of a dialogue between human and machine. It is an object that is unique in its aesthetic and production process.

Our objective was to significantly reduce material usage and create an ultra-lightweight object by working not with mass, but with the absence of mass. Tamu is the result of a dialogue between human and machine. It is an object that is unique in its aesthetic and production process.

For over 20 years, Patrick Jouin iD has been at the forefront of 3D printing in design, embracing this technology to create lightweight, single-piece objects manufactured in a single process with minimal material and waste.

This commitment to innovation responds to the ecological concerns of our time. Experimenting with 3D printing has allowed us to push the boundaries of design, creating iconic pieces such as Solid chair (2004), One Shot (2006), Bloom (2010), Banc Monolithique (2017), Tamu (2019) and the upcoming Ta.tamu in 2025.

The Journey (2004-2017)

Solid, I.MATERIALISE

|

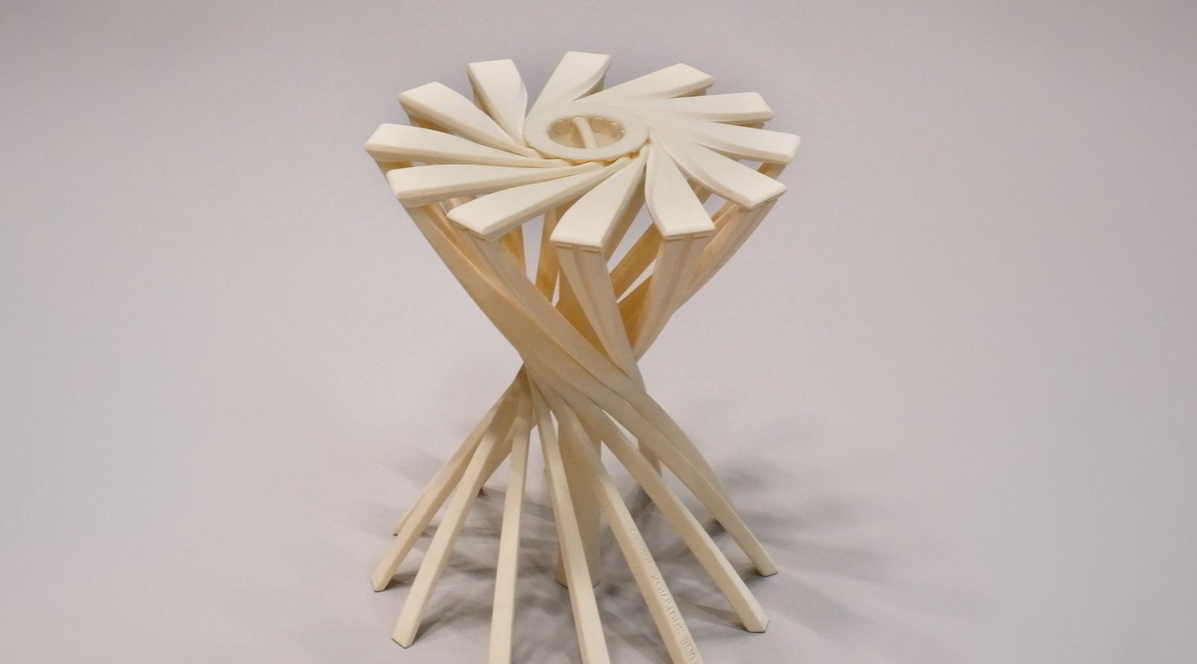

One Shot, I.MATERIALISE

Designed in 2006 for I.MATERIALISE, One Shot is one of the first 3D-printed pieces of furniture ever created – a folding stool made in one piece using selective laser sintering. No axle, no screw, no spring, no visible hinge: One Shot unfolds fluidly, solely by gravity, from a compact bundle of polyamide rods into a stable seat. Up to 15 stools can be printed simultaneously in a single production cycle, thanks to its minimal volume when folded. One Shot is both a feat of engineering and an iconic design piece. It is currently being presented at the MoMa for the Pirouette: Turning Points in Design exhibit that celebrates designs that pushed limits and redefined our relationships to objects.

One Shot and the Solid collection profoundly marked the history of design. With these pioneering works, Patrick Jouin iD revealed the potential of 3D printing in furniture and product design; In her article “The Classics, Circa 2050” for The New York Times, journalist Julie Lansky ranked One Shot along Solid C1 and C2 as second only to the iPhone in a projected canon of early-21stcentury design classics.

One Shot and the Solid collection profoundly marked the history of design. With these pioneering works, Patrick Jouin iD revealed the potential of 3D printing in furniture and product design; In her article “The Classics, Circa 2050” for The New York Times, journalist Julie Lansky ranked One Shot along Solid C1 and C2 as second only to the iPhone in a projected canon of early-21stcentury design classics.

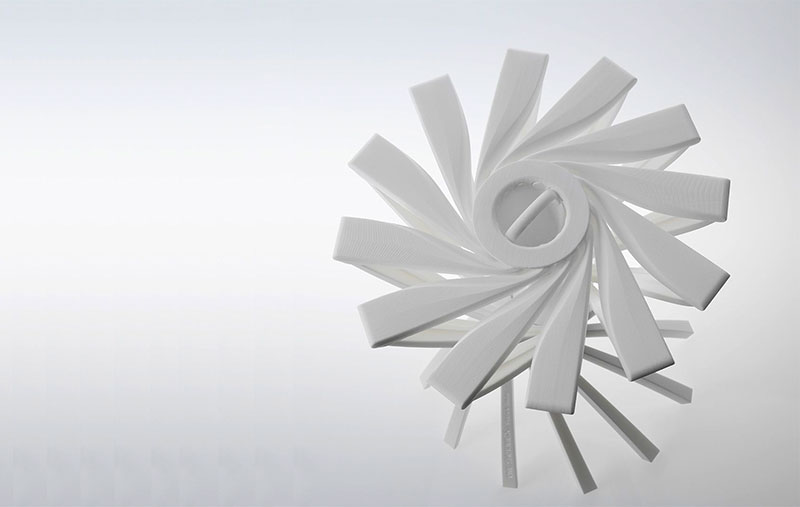

Bloom, I.MATERIALISE

The Bloom lamp opens like a flower, demonstrating how elegance, sensibility, and technological innovation can coexist. Produced using 3D printing, specifically selective laser sintering, it is composed entirely of a single piece –including its hinges and sliding parts. The user can control light intensity by unfolding the piece, merging function and poetry in a seamless gesture.

Banc Monolithique, Palais de Tokyo

Created in collaboration with Professor Marescaux, a specialist in minimally invasive surgery, the Banc Monolithique is inspired by the hidden complexity and precision of natural structures. This piece marks a new chapter in our 3D-printed design research, driven by the ambition to reduce material use and production waste.

Made entirely in one piece using selective laser sintering, its simple form conceals a sophisticated internal architecture: hundreds of nerve-like stems provide the rigidity required to support human weight while keeping the piece exceptionally lightweight.

Made entirely in one piece using selective laser sintering, its simple form conceals a sophisticated internal architecture: hundreds of nerve-like stems provide the rigidity required to support human weight while keeping the piece exceptionally lightweight.

✕