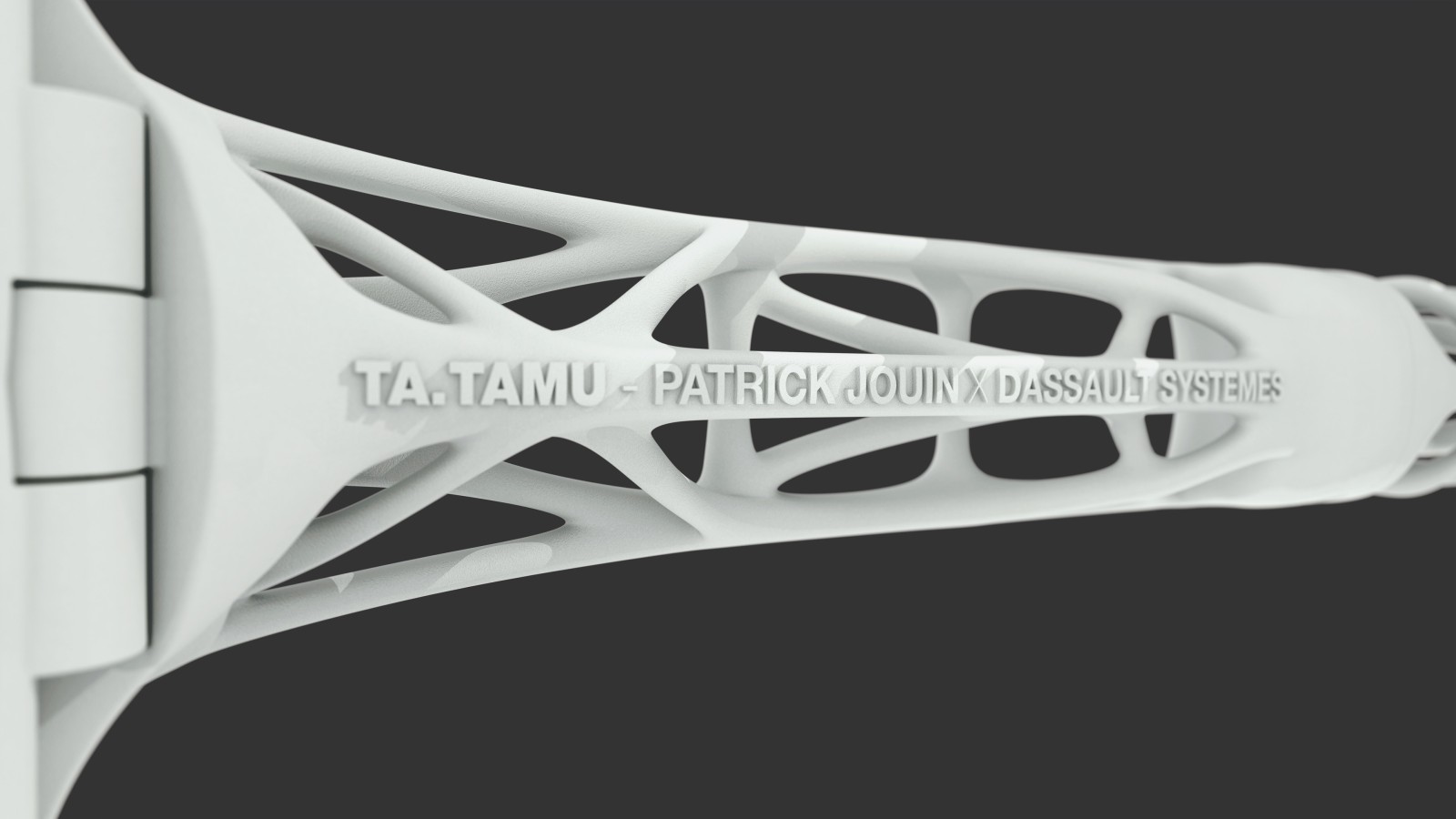

Ta.Tamu

Dassault Systèmes

TA.TAMU

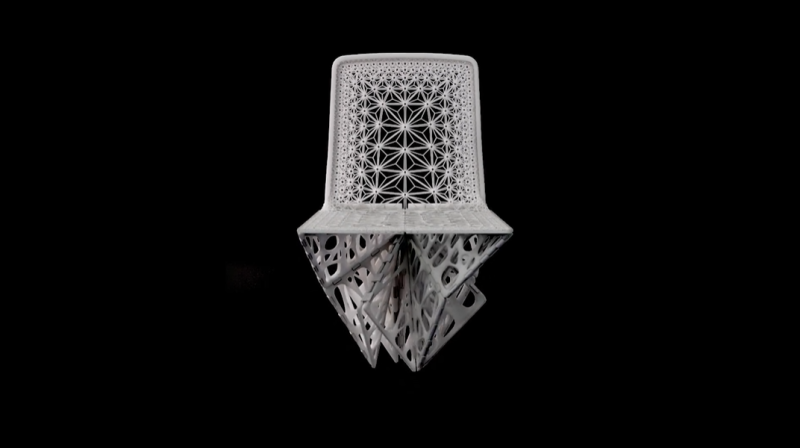

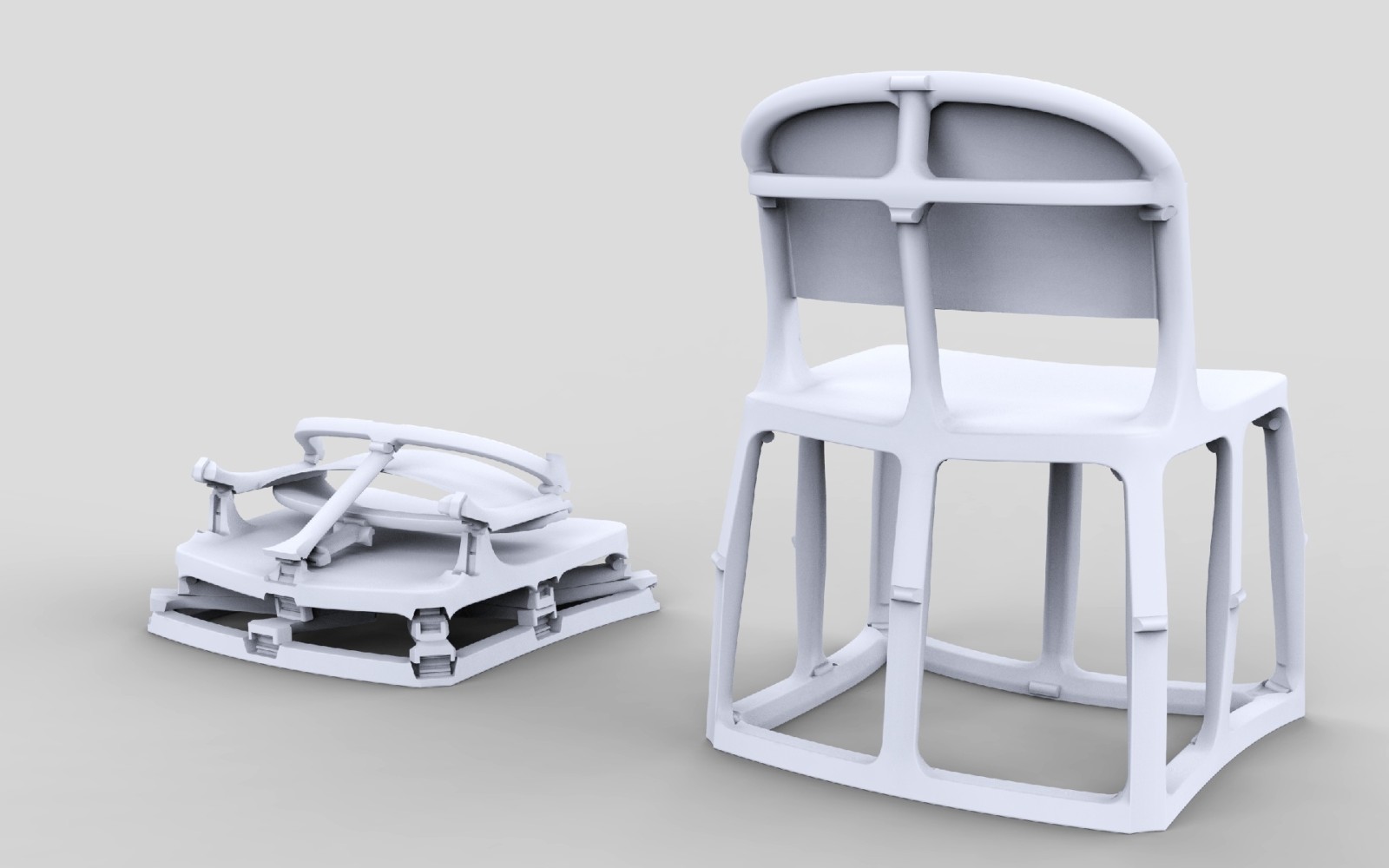

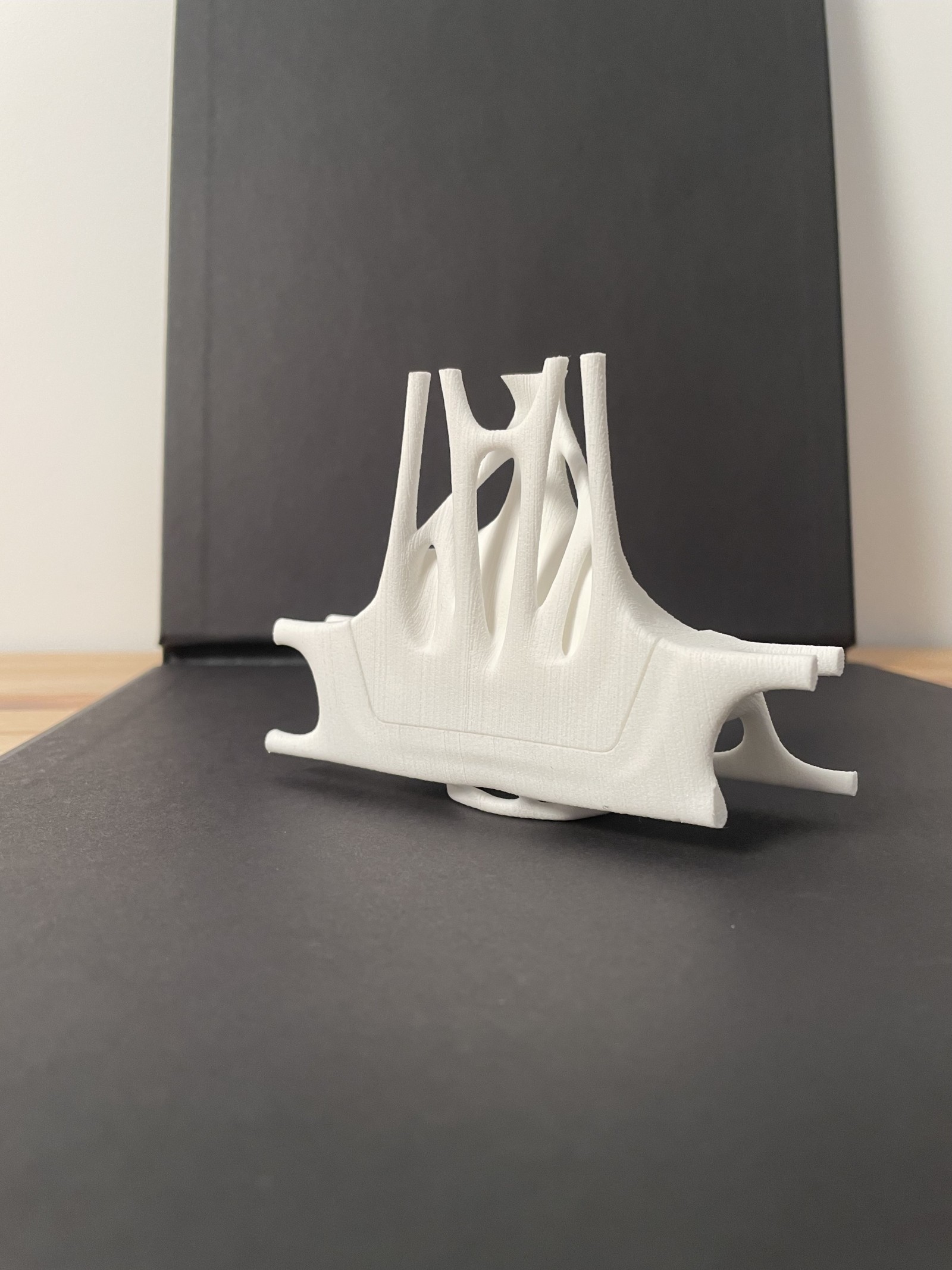

The first 3D-printed chair, folded, with no assembly, using a minimum of material

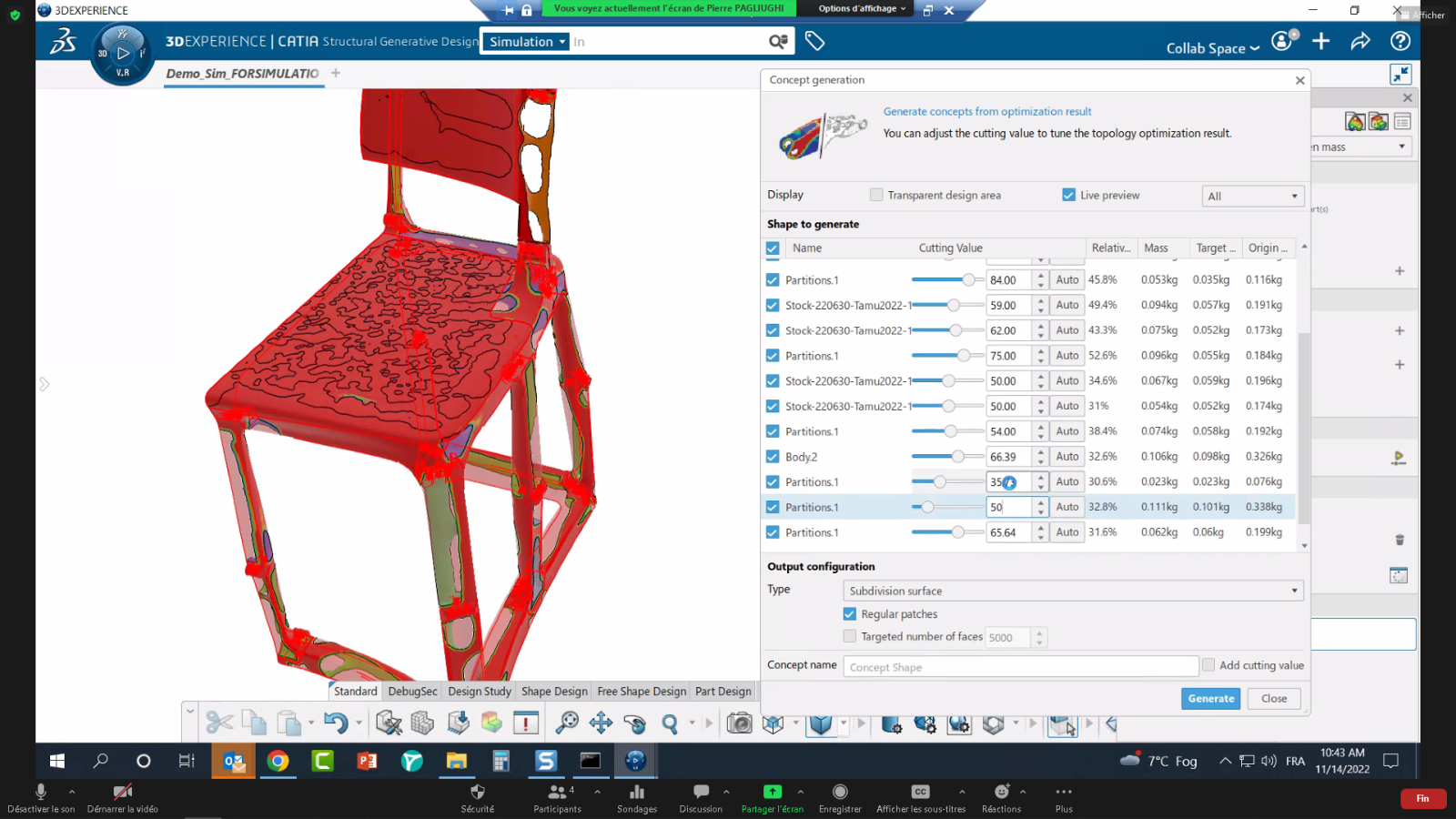

Through advanced topological optimization, it uses only the necessary material, achieving a radically lightweight yet functional form. Printed in one go, it emerges folded to fit the printer’s volume and unfolds seamlessly after fabrication.

Its structure draws inspiration from bone logic: matter only where needed, strength with minimal weight. Composed of 23 elements connected by 33 joints, each tolerance was refined to the millimeter, tight enough not to fuse, yet loose enough to move instantly.

The project embodies a patient dialogue between intuition and computation, where each iteration, test, and adjustment shaped a chair that is both precise and expressive.

A Form That Is Not Drawn: Rethinking Aesthetics in the Age of Optimization

by Patrick Jouin

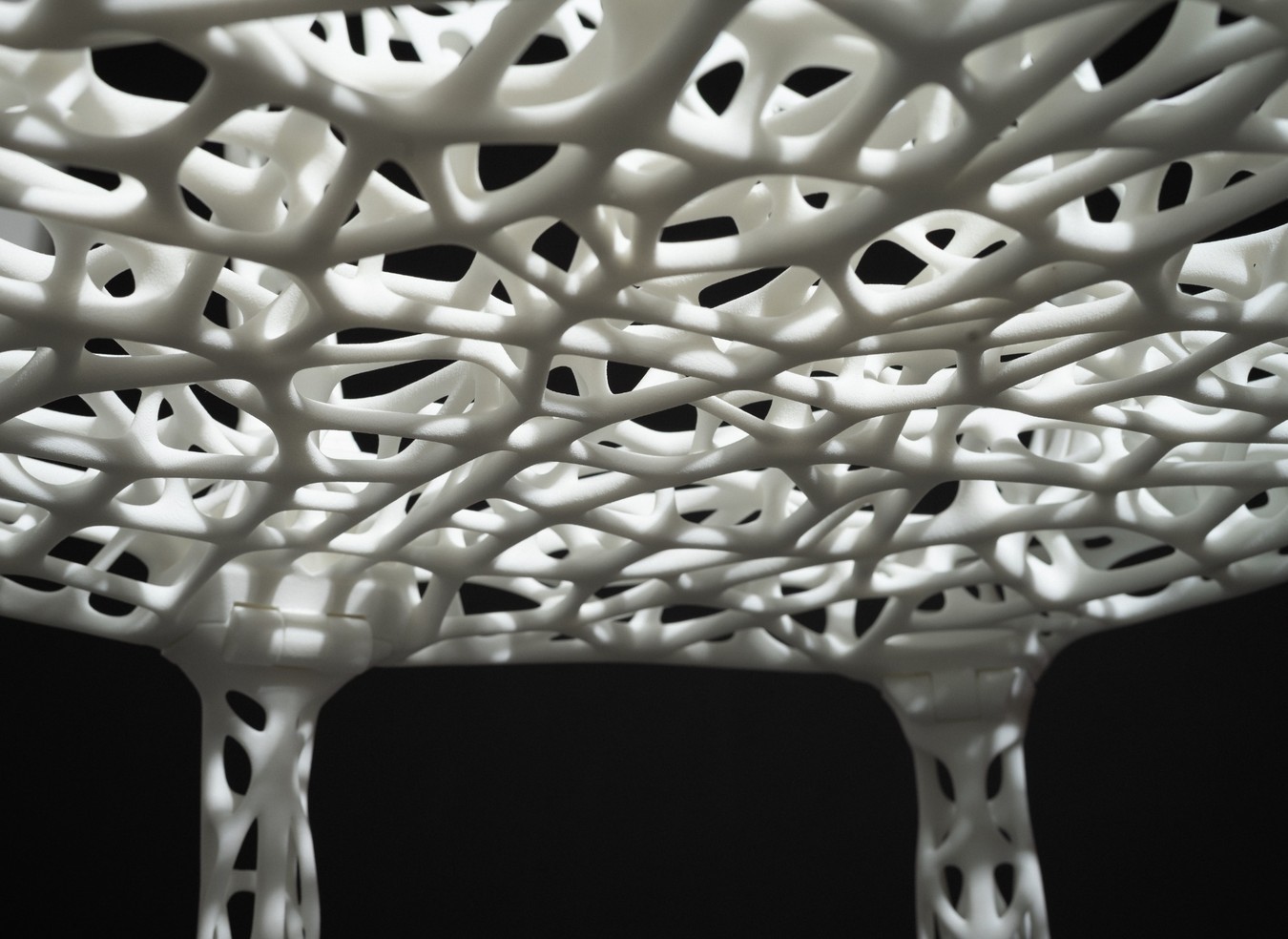

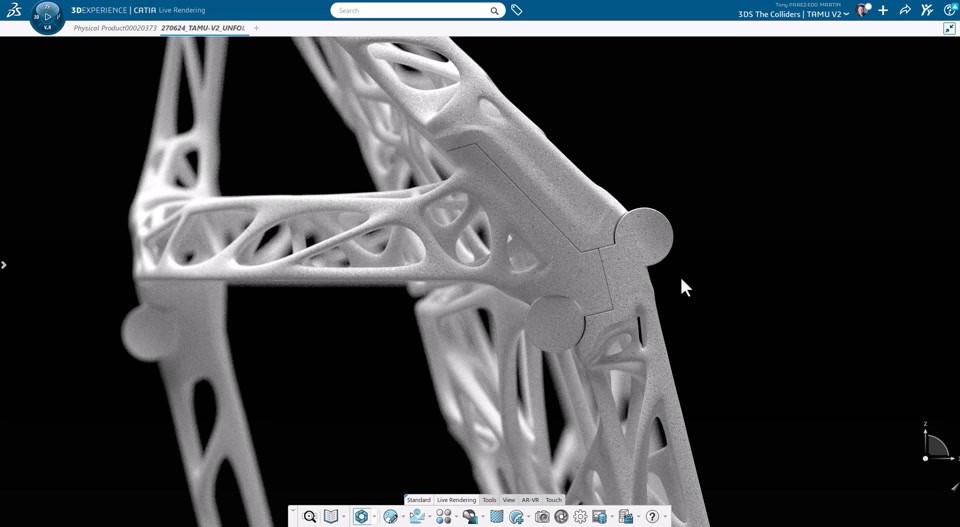

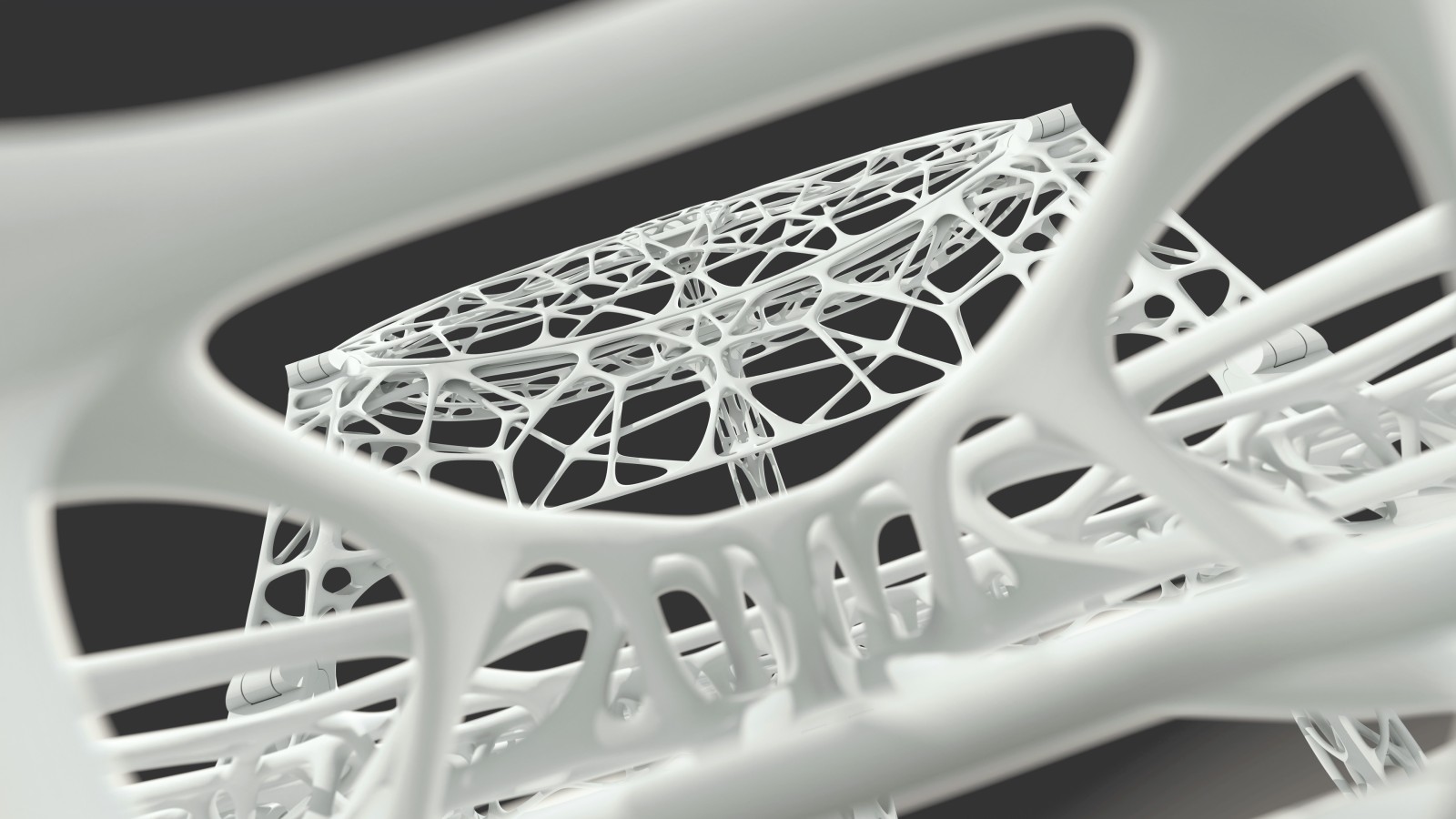

The result is striking: an organic, almost living structure that evokes a skeleton or the branching of a plant. It is not “drawn” but shaped by forces, the way a bone takes form. This raises a question: how can one think aesthetically about a form that is calculated rather than stylized?

TA.TAMU redefines purity. Where modernism favored straight lines and smooth surfaces, here the economy is structural rather than visual. As Simondon wrote, “form is the expression of a becoming”: it arises from a process, from a tension between matter and information.

The role of the designer shifts. He no longer dictates a form but creates the conditions for its emergence. The software becomes a partner, a co-author, confirming Flusser’s intuition: “The designer of the future will no longer draw, he will program.” This aesthetic of what is strictly necessary recalls the logic of the living: adaptation, efficiency, balance. It is not decorative, but consequential. It reveals an immanent beauty, echoing John Dewey’s words, “the organization of means in the direction of an immanent end.”

TA.TAMU is a proposal rather than a style, a pathway toward an aesthetics of necessity that is attentive to resources, to life, and to the alliance between human intuition and computational logic. The designer becomes the curator of generated forms, the one who lends them legibility and meaning. The future of design may unfold here, in the discovery of a beauty that does not impose itself on matter, but emerges by letting matter speak.

MATERIAL: ECONOMY & PRECISION

TA.TAMU is the result of a long-term exploration where material, movement, and transformation are central to Patrick Jouin’s work.

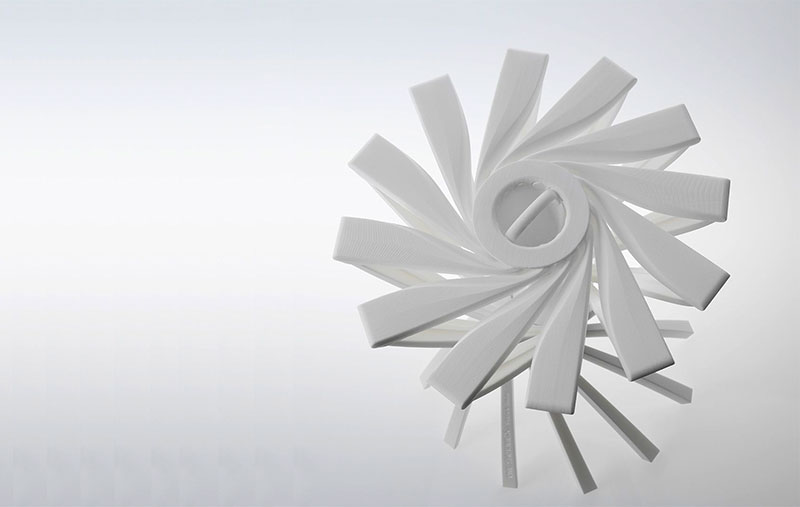

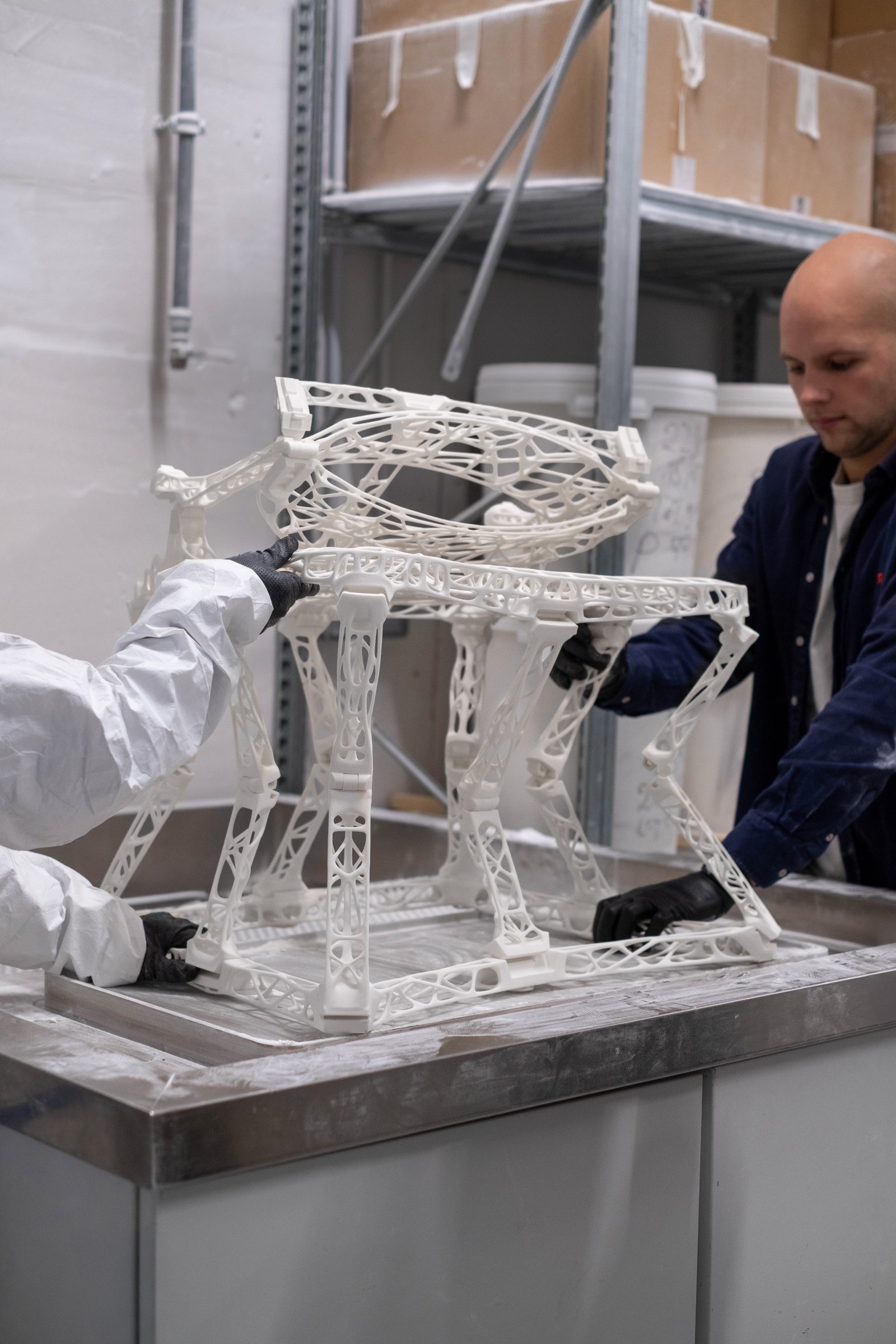

As early as 2004, with Solid — the first 3D-printed chair — he began a journey inspired by natural structures, by grass growing, and by the invisible forces that shape matter. This approach has taken many forms over the years: One Shot, a folding stool printed in a single gesture; the monolithic bench at the Palais de Tokyo, hollowed out from within to lighten its structure while retaining its sculptural presence.

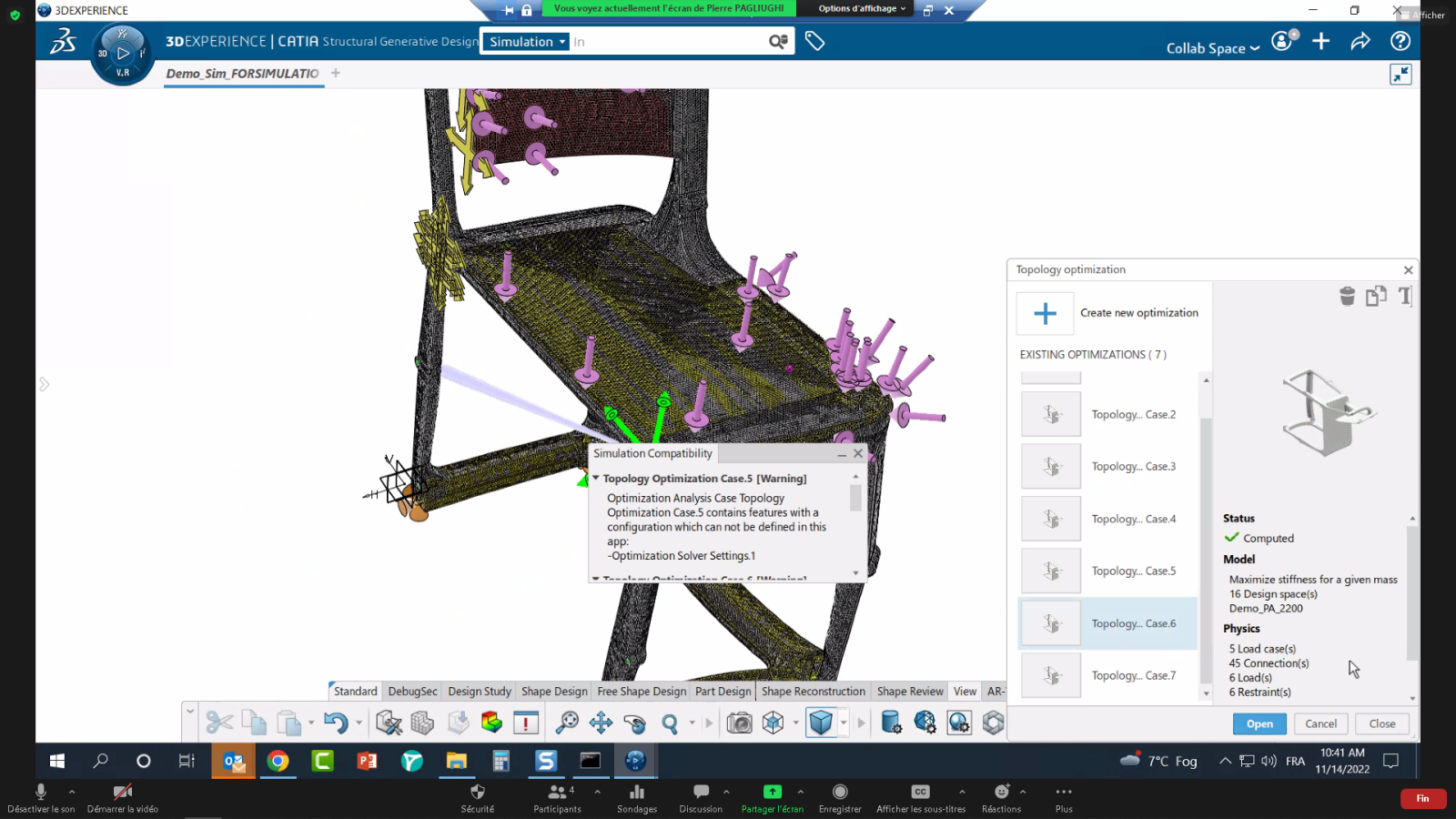

Since 2019, Patrick Jouin has been engaged in a collaborative dialogue with Anne Asensio and the teams at Dassault Systèmes, exploring themes of folding, deployment, and optimization. TA.TAMU was born from this intersection of design, science, and technology — a prototype that has become a method.

Together, they combined intuition with the power of digital tools, opening a prospective field: How can we design differently? How can constraints become a design language? How can we create forms tailored to contemporary materials and fabrication processes? TA.TAMU is a seat weighing just under 3 kilos, printed in 24 hours, and ready for use straight from the printer.

A skeletal structure, almost alive, that conserves every gram without compromising on elegance, precision, or the intelligence of the gesture.

TA.TAMU is a chair.But it could be much more than that:a method. A manifesto. A turning point.

PROCESS

It is first and foremost the most effective way to reduce the weight of an object,but it is also a deliberate stance in response to societal and environmental challenges. Less material means less energy in production, less pollution, less waste.

This chair is firmly rooted in a circular economy approach, integrating the full lifecycle of matter, sourcing, manufacturing, distribution, while ensuring the recyclability of each component.

"We are in an era where we produce more than we need. With the help of new collaborative technologies, we are now able to create more efficiently, generating less waste, right from the design process."- Patrick Jouin

Read more

Additional information

Printed by ERPRO

Credits