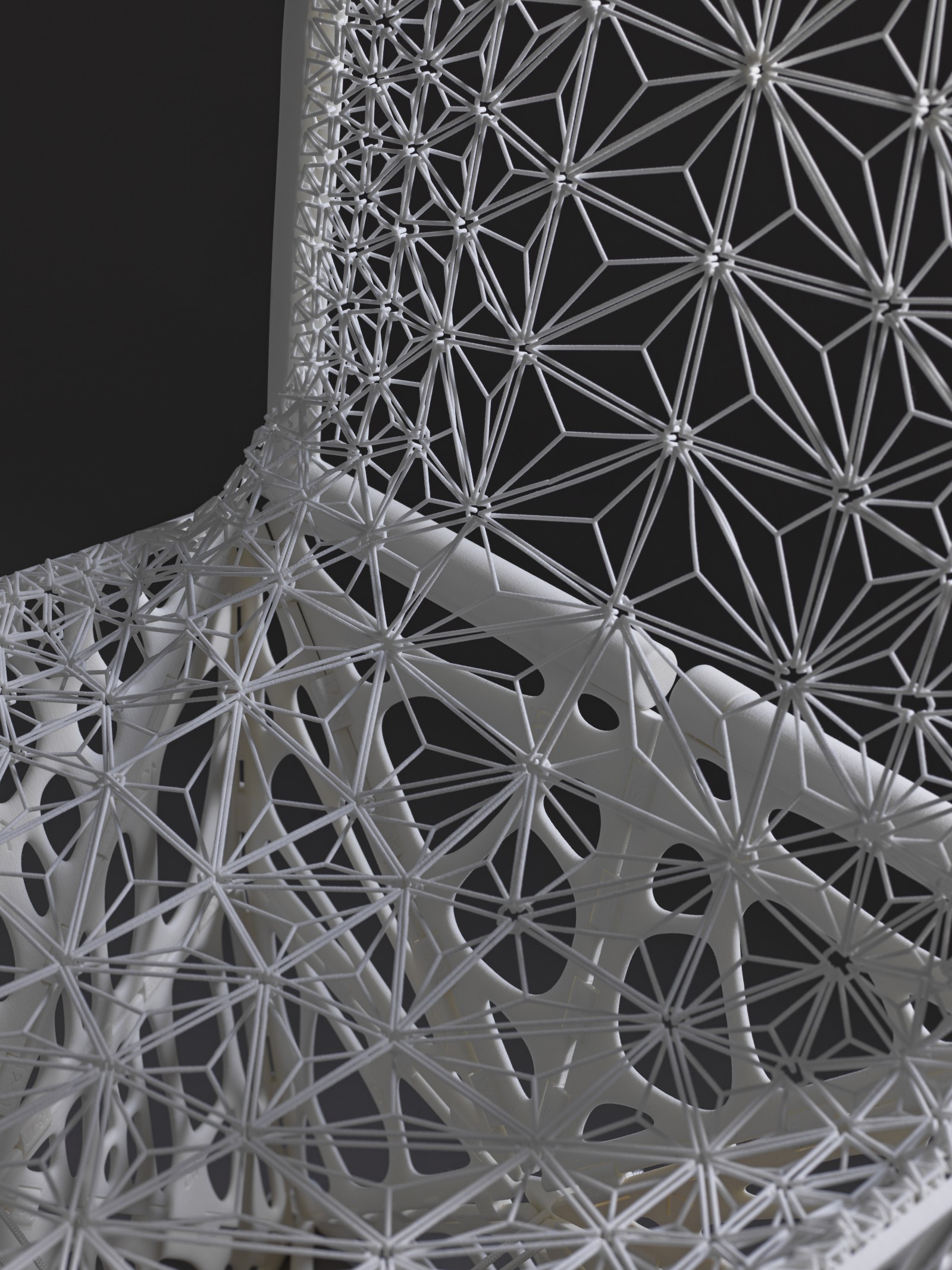

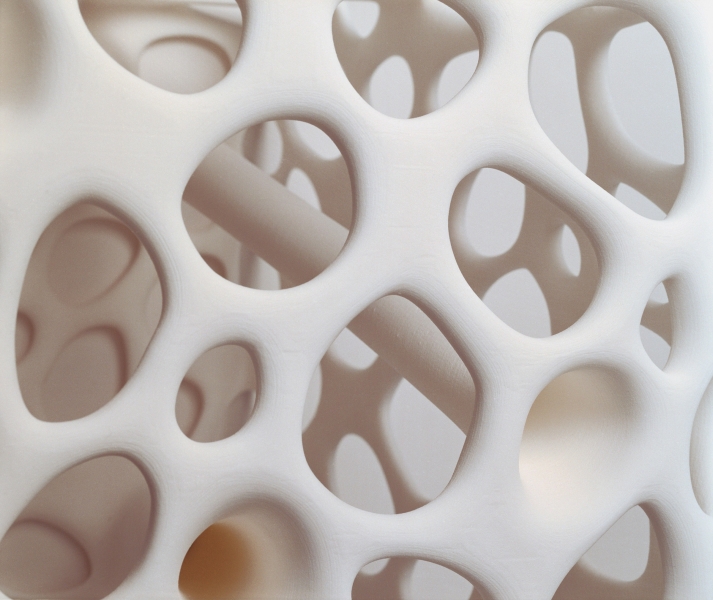

Passionate designer, Patrick Jouin has been exploring the uses of 3D printing and the power of machines for 15 years. In 2004, his "SOLID" collection, the first series of 1:1 furniture made using these new technologies, entered the history books and the permanent collections of major museums.

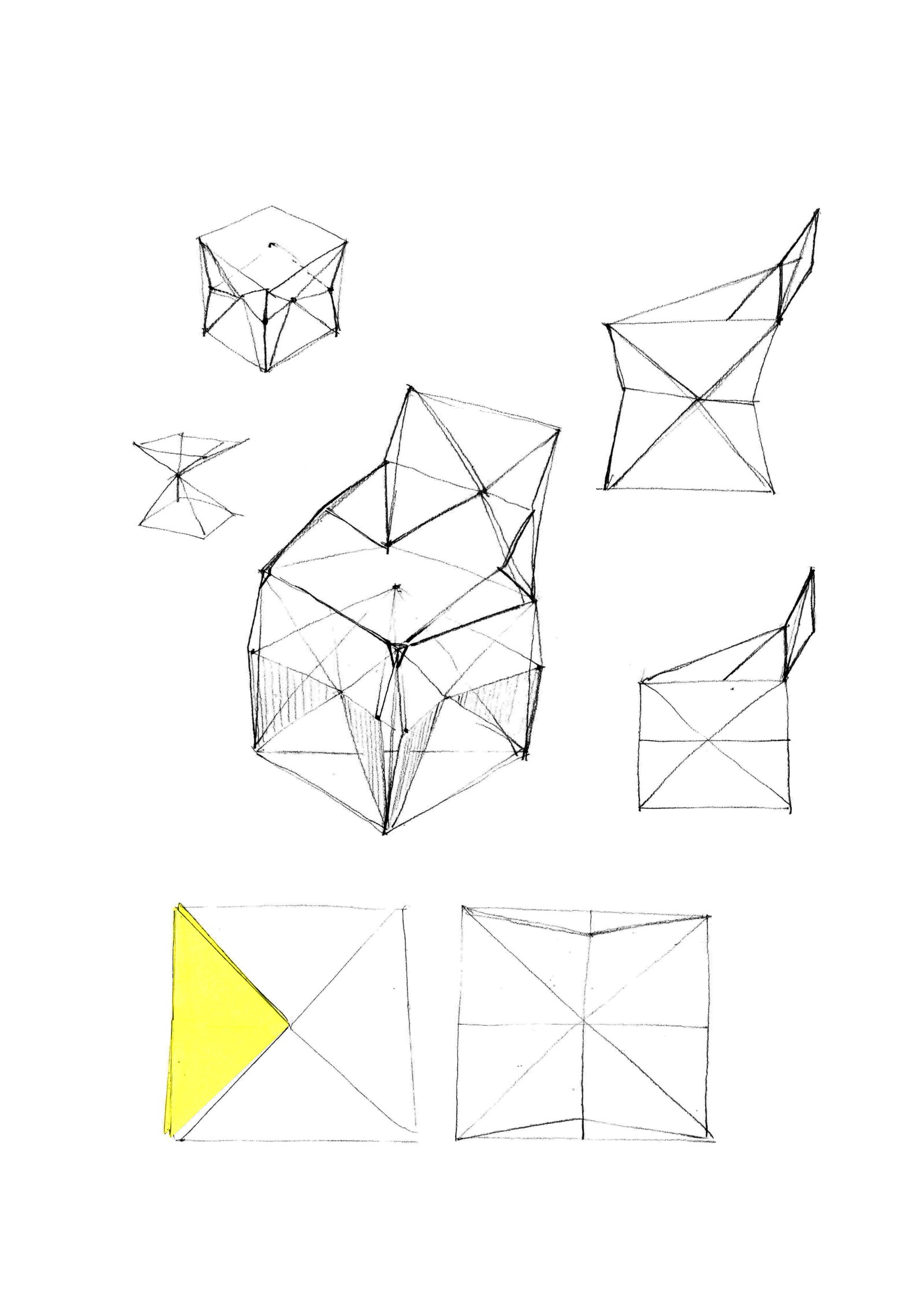

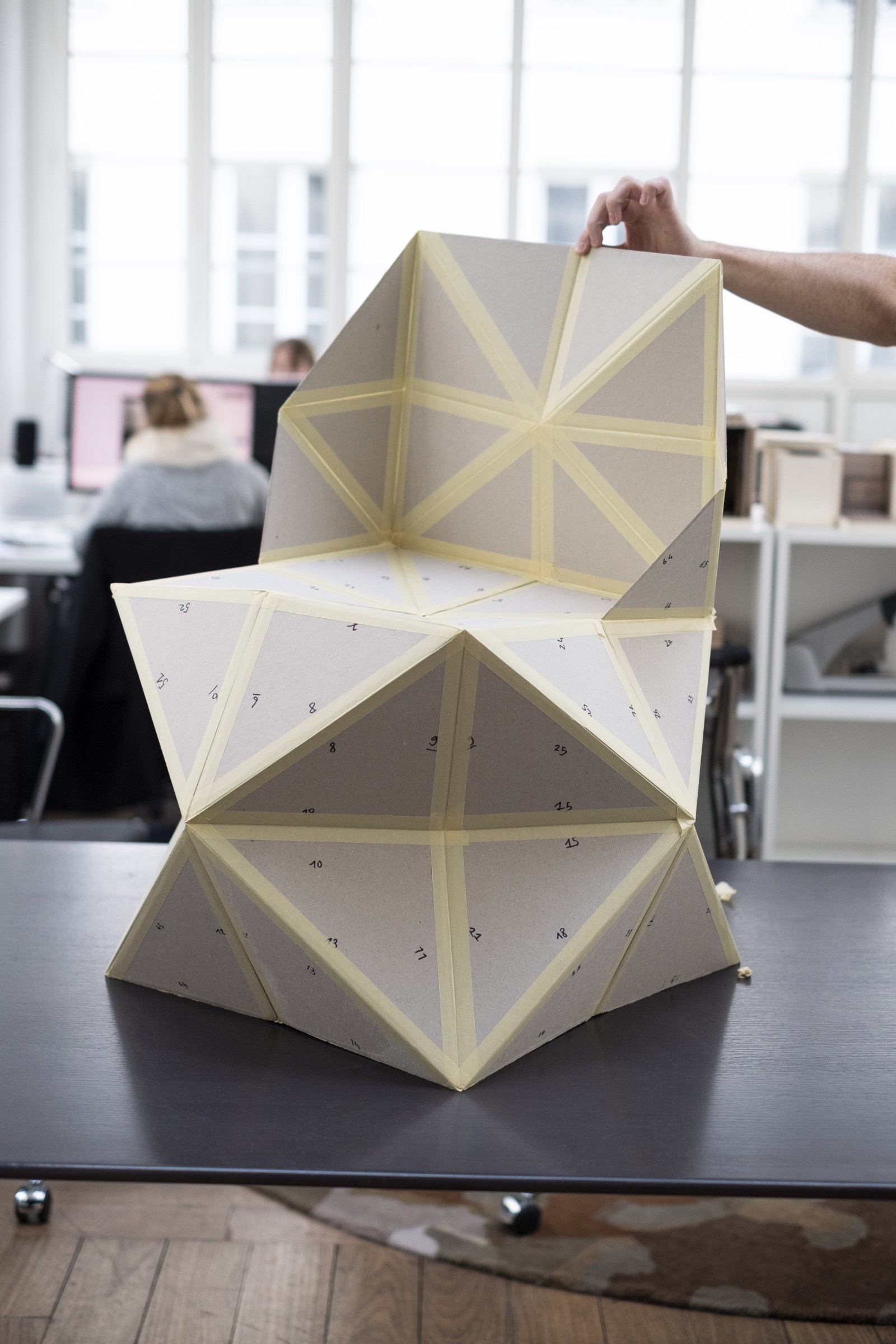

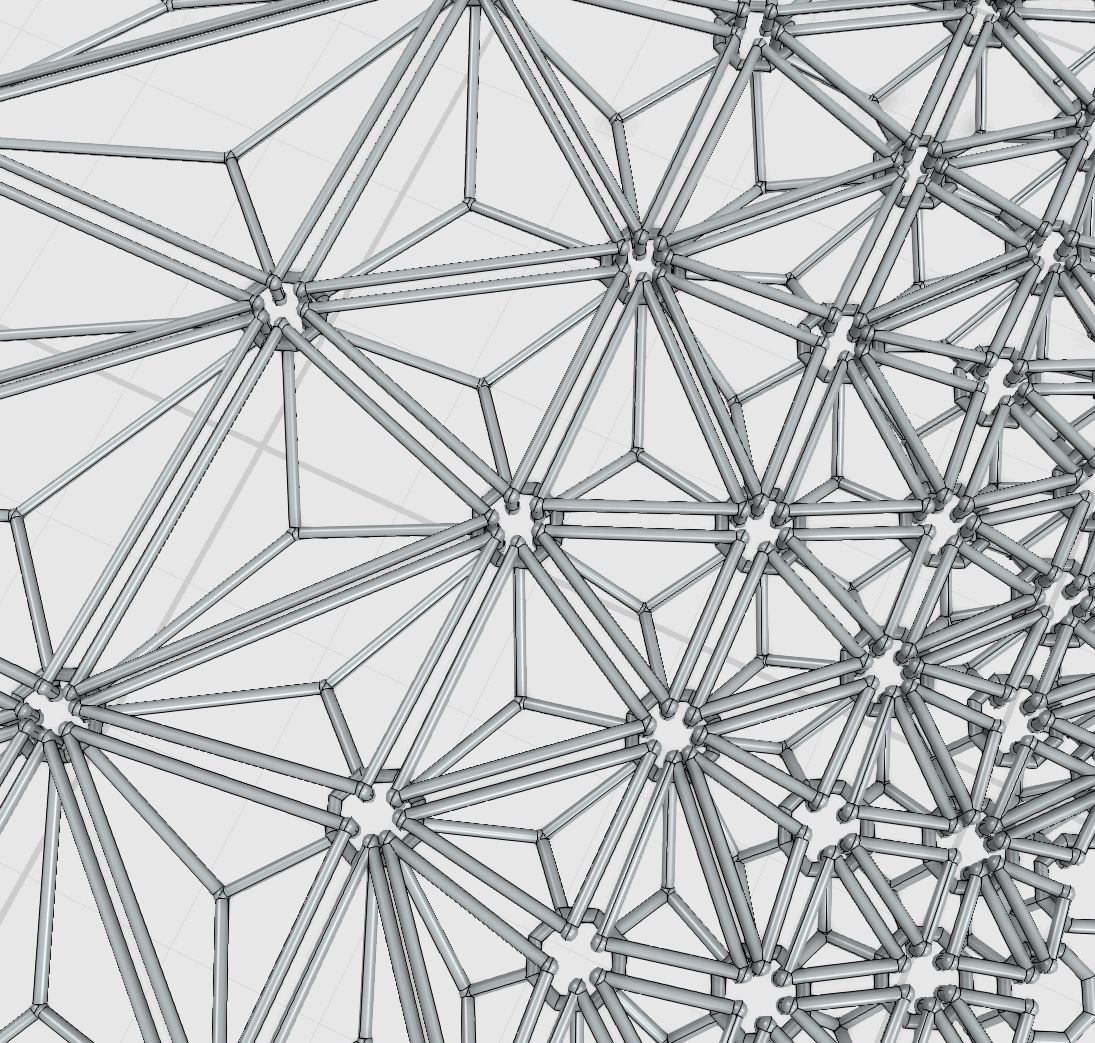

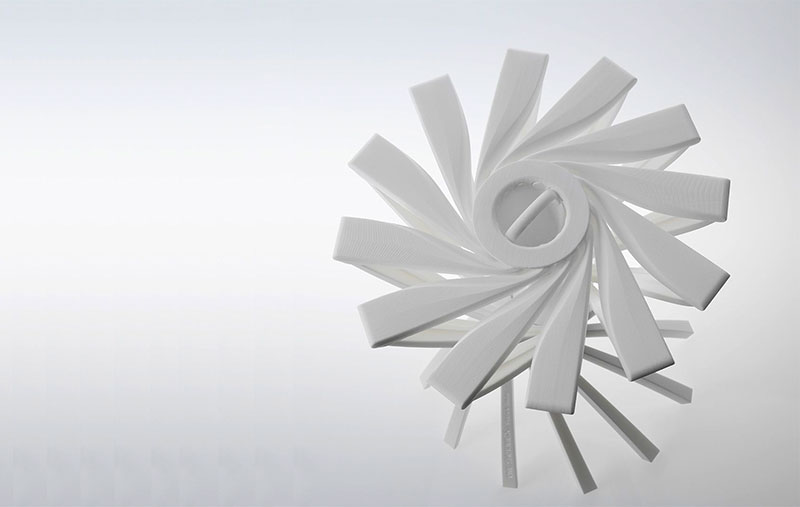

In 2019, he unveiled a groundbreaking research project inspired by the efficiency of nature: the Tamu prototype. The fruit of a dialogue between designer and machine, Tamu is a folding chair that uses as little space and material as possible to manufacture.

Dassault Systèmes has supported Patrick Jouin in his approach, making its resources available through the 3D Experience collaborative platform to help him meet this challenge.